Automobile

bridges with spans up to 150 feet have been built of bamboo by Jorg

Stamm in Colombia (see the Conbam site below for more on Jorg)

photo by Jorg Stamm

Bamboo has been

documented with over 1,500 different uses. In the area of building,

that includes fences, gates, trellises, and every part of a

structure. Bamboo tools, utensils, and buildings are an important

part of life for half the world's population. In temperate climates

around the world, bamboo supply can be maintained indefinitely while

maintaining erosion control, watershed integrity, soil health. What we lack is Summer rain.

As a building

material, bamboo is special both because it handles long spans

and has such intrinsic beauty.

The main reason we can – for the first time – look seriously

at this plant is the joinery system developed by Simon Velez and

others in Colombia.

It is the process

of establishing the production system appropriate to our culture and

time that is most important to think through now. Gaining access to

inexpensive land not usable for any other purpose, choosing

appropriate species, allowing the time for maturity, understanding

the aesthetics of working with cylindrical materials in a

predominantly rectilinear society, learning to find exceptional

working stock, and developing a design approach that takes full

advantage of both the strength and beauty of the timber bamboo –

these are our challenges.

Websites

American Bamboo Society

-- especially

the Species Source List (all bamboos in cultivation in

the U.S., sizes, temperature & shade tolerances) http://www.bamboo.org/abs/

1000 things

bamboo -- http://www.bambus.de/infos/1000/indexx.php

Building the ZERI

pavilion -- http://www.zeri.org/pavilion/slideshow/pav_small/slideshow.asp

German university site

-- http://www.conbam.de

Books published by INBAR

-- http://www.panasia.org.sg/ecom/mos/user/webdriver?MIval=MOS&START=1&WINSIZE=5&orgid=33&catid=4

Best source of bamboo

books in the U.S. -- http://www.bamboodirect.com

Bamboo Flooring --

http://www.4specs.com/s/09/09649.html

Code approval in the U.S. -- http://www.icbo.org/ICBO_ES/Acceptance_Criteria/pdf/ac162.pdf

International standards by

the author of the ICBO Acceptance Criteria, Dr. Jules Janssen -- http://www.bwk.tue.nl/bko/research/Bamboo/iso.htm

In Spanish, from the country

getting the most from bamboo -- http://www.asosismica.org/

Walk through several Velez

buildings -- http://home.earthlink.net/~montecito/irongrass.htm

Thoughts about bamboo flooring

from myself and Christi Graham -- http://www.kqed.org/topics/home/homeimprove/healthyhome-feature3.jsp

Find uses for

the much more common small diameters and easily-made splits; Bamboo

in tension is at its best (photo by Jaqueline Lytle)

Gazebos, trellises,

and arbors like the one I did above are some of the

first structure types that people think are associated with

bamboo. They're great, as long as one accepts that they won't

last long once exposed to the sun and rain. Bamboo performs

about like hardwoods and our douglas fir structural lumber, which

means it splits in the first couple of years of exposure, then it

bleaches gray in the sun. As long as the powder post beetles

don't find it, it will last for years, as long as you're ok with the

way it looks. Trellises can last for 20 or 30 years, less in

humid, wet climates. And the ability of this lightweight,

strong material to totally transform landscapes quickly is

unsurpassed. But, that's not even the best use of

the material. Our challenge is to find ways to use it

indoors where it's luster is preserved and it can continue to

look attractive indefinitely.

Sustainability

As an architect

with an interest in maintaining my supply of building materials, I

find that bamboo meets the basic criteria for continuous use. It is:

Renewable - The

Phyllostachys varieties, most suitable for growing and building in

the U.S. where we must deal with frost, will grow 12-18 inches a day

once a grove is established. Culms (the living poles) emerge as

large as they will ever be in that first six-week spurt, then spend

the next three years replacing sugars and water with silica and

cellulose. Structurally, they are only useful after that third year,

which is about when the culm is not needed by the plant.

5” dia. P.

vivax in the SF bay area.

The roots extend into the lawn, excess shoots are

transparently mowed

Plentiful - Our current

meager U.S. supply of timber-quality bamboo can increase manifold

within a decade with species selection appropriate to the

microclimate, water, and nutrient availability. For now, temperate

varieties such as Moso are being imported from Asia. These are well suited to

being grown here.

Local - Bamboo concentrates

a large amount of fiber in a small land area, creating that rare

situation in which a single person can be both producer and consumer

of a building material. A bamboo builder is not dependent upon the

whims of the marketplace and can create a long-term source of

material. Few other materials, besides earth, can make such claims.

Waste-reducing - As is

nature's general practice, nothing goes to waste. The leaves are

high in nitrogen, making good feed for livestock. Any fallen leaf compost goes

to fertilize the next generation. http://esi.athenstn.com/wwt/Bamboo_Bioremediation.html

But, even more enticing are the statistics for pulling carbon out of

the air, potentially reducing the amount of carbon dioxide that

contributes to the greenhouse effect. According to the people

at the Zero Emissions Research Institute (ZERI) who built the bamboo

pavilion at the top of this page, a bamboo forest can sequester 17

times as much carbon as a typical tree forest. In a country

where a third of the greenhouse gases are attributed to buildings,

imagine a building material that, when used locally, not only

doesn't contribute to global warming, it solves some small portion

of the problem.

STRUCTURAL

PROPERTIES

Bamboo is an

extremely strong fiber; with twice the compressive strength of

concrete and roughly the same strength-to-weight ratio of steel in

tension. In addition, testing (Janssen '97) has shown that the

hollow tube shape gives a strength factor of 1.9 over the equivalent

solid. The reason is that, in a beam, the only fibers doing work are

in the top (compression) and bottom (tension). The center is dead

weight.

The strongest

bamboo fibers have a greater shear strength than structural woods,

and they take much longer to come to ultimate failure. However, this

ability of bamboo to bend without breaking makes it unsuitable for

building floor structures because we have a very low tolerance for

deflection, and few here will accept a floor that feels "alive." On

the other hand, bamboo as a 3/4 inch thick finish floor is an

appropriate substitute for the standard oak because it installs the

same way, is harder and expands less.

Because of the

relative scarcity of timber bamboo in the U.S., one of the best uses

for this giant grass is as a truss, taking advantage of both its

strength and its beauty.

Garden

structure for Eric Lloyd Wright with new forms of triangulation and

stainless bands to resist splits (design by author)

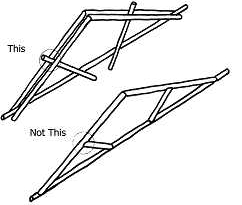

Preferred Joinery

The

“fish-mouth” is the joint required when all the poles are in the

same plane – as in the “Not This” truss shown above. Though common in South

America, it is very labor intensive and most gringos prefer to avoid

it.

The joint of preference is allowed

by the three dimensional truss in the second diagram above,

developed by Simón Vélez in Colombia. This one is a simple bolted

connection, but because the bolt alone concentrates too much force

on the wall of the bamboo, the void between nodes is filled with a

solidifying mortar, increasing the surface area of the joint

significantly.

“Fish-Mouth” Joint