|

Strawbale Thoughts

L a t e s

t N e w s

November 2005:

Author David Pearson was nice

enough to include one of our houses in his most recent book,

Designing Your Natural Home, (the cover is in the upper

left corner of this page) just released from Harper Collins.

The book is done well and David has had a great track record in

finding ways to get ideas about ecological design to reach

mainstream readers. So, once again, I think he has really

achieved something here.

The July/Aug 2005 issue of

what's now called Natural Home and Garden has a list of the

Top 10 Eco-Architects, and they were

kind enough to include us.

Check out the March/April 2004 issue

of Natural Home magazine. We're on the cover!

For more

pictures, you'll have to buy the issue as it's not available

online. For more

pictures, you'll have to buy the issue as it's not available

online.

T h e S

y s t e m

Wood construction has had a few hundred

years' head start on straw bale construction. Now that most

people have at least heard of building with straw, we're trying to

refine  an intuitive system of

building that just makes obvious sense. an intuitive system of

building that just makes obvious sense.

I like building with straw because --

even after working on relatively few buildings -- it's clear

that it works better than wood. It's pure insulation with no

energy leaks through the framing; with plaster, it just doesn't

burn (try throwing your phone book into a fire), there are no

openings for rodents and insects to run around, AND there's nothing

there for them to eat anyway. Done right, the system is

amazingly strong, putting plywood to shame (see testing

results), but the most crucial advantage over conventional

construction is that straw walls have quite a capacity to

hold lots of water before any kind of rot can begin. In any

building system, water will inevitably get into the assembly

sometime, even if just from the breathing of the occupants or high

humidity. But if composting can only begin once moisture

reaches 28%, or if almost a third of the contents of that two foot

thick wall of solid cellulose needs to be water, you have to

REALLY be trying to get that wall so totally saturated that there

are problems. Though I haven't worked in an extremely humid

climate, I think straw is better suited for those conditions than

wood framing with moisture-resisting fiberglass insulation because

the moisture has no option other than sitting on the relatively

small surface area of the wood framing.

The most important idea is avoid vapor

barriers so the moisture can get out.

Some of the

gorgeous colors we've been getting just from the local

clay. Some of the

gorgeous colors we've been getting just from the local

clay.

One of the authors of the Straw Bale

House Book, Athena Steen, was visiting awhile ago and casually

mentioned that of the many experiments she and her husband Bill

have done with bales, she has never found rot under an earthen

plaster. DING! My favorite assembly is to put a

lime wash over earthen plaster on the bales because the clay

constantly attracts vapor out of the bales and the lime hardens the

surface of the plaster to prevent erosion. Water vapor

molecules are 100 times smaller than liquid water, so this assembly

keeps the water molecules out of the wall but still allows vapor to

escape. The problem with cement-based plasters is they are

much less permeable, and moisture gets trapped between the wall and

the plaster.

L o a d B e a r i n

g ?

When you first think about it, having the

straw carry all the weight of the structure makes sense. It

settles evenly, and very little wood is needed.

This project was possible

because of the Owner/Builder exception to the building code that

exists in two counties in California: Humboldt and Mendocino.

A person who lives in a place for at least 5 years can build

whatever they want, and they don't need to explain anything to the

building department. But they ARE condemned to stare at their

mistakes daily. My personal opinion is that there must be a

happy medium between over-regulation and NONE, but this project was

allowed to explore the load-bearing possibilities. And

other than anchor bolts, there were no metals used in the walls to

attract moisture on cold nights (a fishing net mesh went over the

outside and inside) This project was possible

because of the Owner/Builder exception to the building code that

exists in two counties in California: Humboldt and Mendocino.

A person who lives in a place for at least 5 years can build

whatever they want, and they don't need to explain anything to the

building department. But they ARE condemned to stare at their

mistakes daily. My personal opinion is that there must be a

happy medium between over-regulation and NONE, but this project was

allowed to explore the load-bearing possibilities. And

other than anchor bolts, there were no metals used in the walls to

attract moisture on cold nights (a fishing net mesh went over the

outside and inside)

N o n L o a d

B e a r i n g

But there is an argument for a

separate structure. First, the discussion with the building

department is usually not so simple when you announce that straw is

going to hold up your whole house. Second, during

construction, the structure is subject to rain for some

period while the roof is built. And third, there are often

times when you'd like something solid to nail to (like door

frames, electrical boxes and exterior

reinforcing mesh).

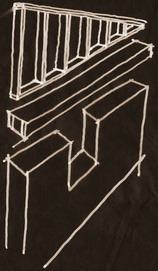

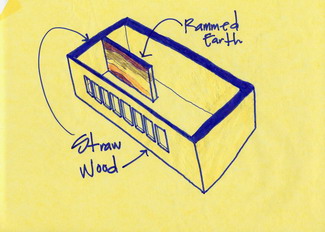

So, lately we have taken to this

system of building boxes out of 2x4's and plywood, making

surprisingly strong composite posts and beams.

Then make sure that you really want a

strawbale WALL. Turns out most of us want a bunch of windows

with a little bit of wall over in the corner. Be honest and

decide if you really need a big, solid, continuous chunk of

insulation.  Then, just put

the straw walls on the sides of the house that really demand them:

north and west in our temperate climate of northern

California. Since the south should be full of windows, just

put in some small wood framing and don't bother with straw

there. Just put the straw in a long, flat wall if you

can. Where there's a sloping wall, frame it out of

wood. Then, just put

the straw walls on the sides of the house that really demand them:

north and west in our temperate climate of northern

California. Since the south should be full of windows, just

put in some small wood framing and don't bother with straw

there. Just put the straw in a long, flat wall if you

can. Where there's a sloping wall, frame it out of

wood.  And if you are tempted

to build a big mass wall, like rammed earth -- put it INSIDE

the building where it will do some good and hold onto your precious

heat rather than drain the heat right out. And if you are tempted

to build a big mass wall, like rammed earth -- put it INSIDE

the building where it will do some good and hold onto your precious

heat rather than drain the heat right out.

R e s i s t i n

g E a r t h q u a k e

s a n d W i n

d

With mesh on the inside and out, tied

through the bales about every 1.5 feet, and nailed all

around the perimeter, the whole assembly is working as a unit.

The only way for the wall to collapse is when thousands of nails

shear off simultaneously. UNLIKELY.

Some people think I talk about this just

because I live where the building codes consider

the most extreme earthquake risk. But, the engineers tell

me that WIND almost always outweighs the earthquake forces.

And don't ever relax when you live where they say the words

"hurricane" or "tornado." I'll take my earthquakes any time,

thanks.

So, with the box post/beam system, you

can complete the framing, with "studs" as far apart as 12 feet, put

the roof on and get it totally waterproofed before you even need

to bring a bale onsite. But the great thing about the box

post/beam system is that it's still very malleable. For

example, if you want to round a corner or angle a window opening,

just hold the box post back a bit and just cob around the curve

or turn the post at an angle. (oh, and these posts will

also put hair on your head, make your toast in the morning and

attract impossibly beautiful people to you daily!)

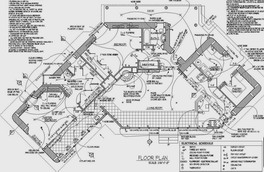

Above is a fairly complex plan.

Notice the white ghosts in the wall that are the box posts. I

feel like we're now at a system that's more intuitive and

shouldn't be as hard to build as some of the early projects which

had a much higher percentage of head-scratching.

The bales can be left out until the

roof is on, and the framing still doesn't use much wood compared to

what we're used to seeing on most jobsites, yet the building

department looks at this as a wood frame building, and they stop

worrying. I'm amazed how strong this assembly is... I watched

the builder, Johannes Stimming run across the box beam at the top of

the above picture and jump up and down in the middle of the 16 foot

span. It didn't move. |